Full Papers at CHI/UIST |

|

[8] AirTied: Automatic Personal Fabrication of Truss Structures

Lukas Rambold, Robert Kovacs, Conrad Lempert, Muhammad Abdullah, Helena Lendowski, Lukas Fritzsche, Martin Taraz, and Patrick Baudisch In Proceedings of UIST'23 (full paper) We present AirTied, a device that fabricates truss structures in a fully automatic fashion. AirTied achieves this by unrolling a 20cm-wide inflatable plastic tube and tying nodes into it. AirTied creates nodes by holding onto a segment of tube, stacking additional tube segments on top of it, tying them up, and releasing the result. The resulting structures are material efficient and light as well as sturdy, as we demonstrate by creating a 6m-tower. Unlike the prior art, AirTied requires no scaffolding and no building blocks, bringing automated truss construction into the reach of personal fabrication. |

|

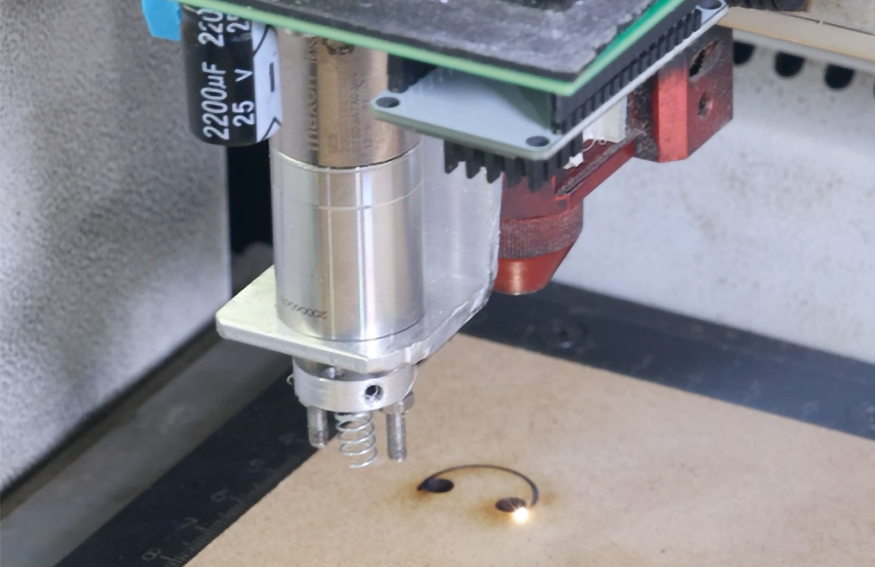

[7] Kerfmeter: Automatic Kerf Calibration for Laser Cutting

Shohei Katakura, Martin Taraz, Muhammad Abdullah, Paul Methfessel, Lukas Rambold, Robert Kovacs, and Patrick Baudisch In Proceedings of CHI'23 (full paper) Kerfmeter is a hardware + software device that automatically determines how much material the laser cutter burns off, also known as kerf. Its knowledge about kerf allows Kerfmeter to make the joints of laser cut 3D models fit together with just the right tension, i.e., loose enough to allow for comfortable assembly, yet tight enough to hold parts together without glue—all this without user interaction. Kerfmeter attaches to the head of a laser cutter and works as follows: when users send a model to the laser cutter, Kerfmeter intercepts the job, injects a brief calibration routine that determines kerf, dilates the cutting plan according to this kerf, and then proceeds to fabricate the cutting plan. Kerfmeter makes it easy to sample repeatedly; we demonstrate how this allows boosting precision past any traditional kerf strip. |

|

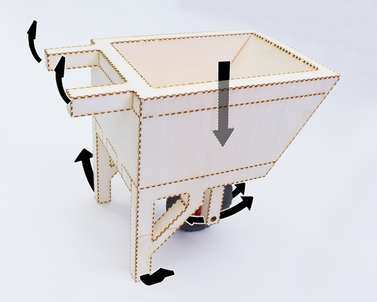

[6] HingeCore: Laser-Cut Foamcore for Fast Assembly

Muhammad Abdullah, Romeo Sommerfeld, Bjarne Sievers, Leonard Geier, Jonas Noack, Marcus Ding, Christoph Thieme, Laurenz Seidel, Lukas Fritzsche, Erik Langenhan, Oliver Adameck, Moritz Dzingel, Thomas Kern, Martin Taraz, Conrad Lempert, Shohei Katakura, Hany Mohsen Elhassany, Thijs Roumen, and Patrick Baudisch In Proceedings of UIST'22 (full paper) HingeCore is a novel type of laser-cut 3D structure made from sandwich materials, such as foamcore. The key design element behind HingeCore is what we call a finger hinge, which we produce by laser-cutting foamcore "half-way". The primary benefit of finger hinges is that they allow for very fast assembly, as they allow models to be assembled by folding and because folded hinges stay put at the intended angle, based on the friction between fingers alone, which eliminates the need for glue or tabs. Finger hinges are also highly robust, with some 5mm foamcore models withstanding 62kg. We present HingeCoreMaker, a stand-alone software tool that automatically converts 3D models to HingeCore layouts, as well as an integration into a 3D modeling environment for laser cutting (kyub). We have used HingeCoreMaker to fabricate design objects, including speakers, lamps, and a life-size bust, as well as structural objects, such as functional furniture. |

|

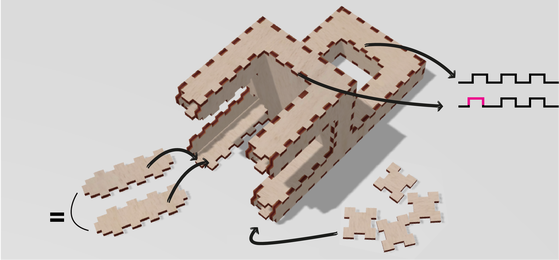

[5] FoolProofJoint: Reducing Assembly Errors of Laser Cut 3D Models by Means of Custom Joint Patterns

Keunwoo Park, Conrad Lempert, Muhammad Abdullah, Shohei Katakura, Jotaro Shigeyama, Thijs Roumen, and Patrick Baudisch In Proceedings of CHI '22 (full paper) FoolProofJoint is software tool that simplifies the assembly of laser-cut 3D models and reduces the risk of erroneous assembly. FoolProofJoint achieves this by modifying finger joint patterns. Wherever possible, FoolProofJoint makes similar looking pieces fully interchangeable, thereby speeding up the user's visual search for a matching piece. When that is not possible, FoolProofJoint gives finger joints a unique pattern of individual finger placements so as to fit only with the correct piece, thereby preventing erroneous assembly. |

|

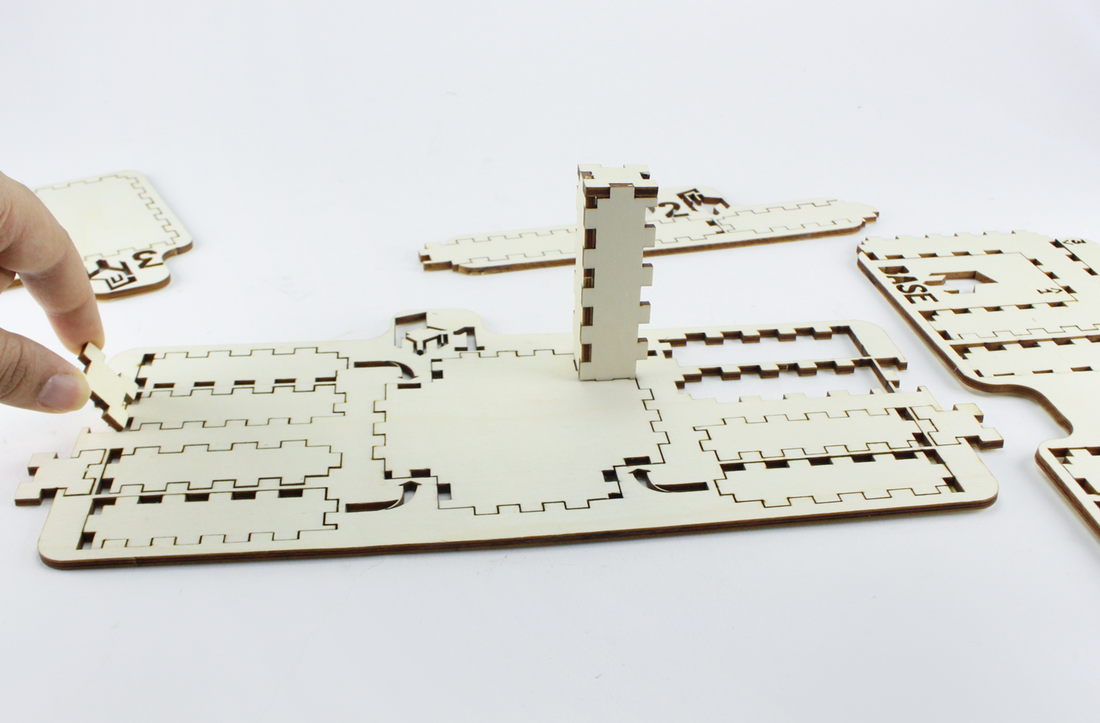

[4] Roadkill: Nesting Laser-Cut Objects for Fast Assembly

Muhammad Abdullah, Romeo Sommerfeld, Laurenz Seidel, Jonas Noack, Ran Zhang, Thijs Roumen, and Patrick Baudisch In Proceedings of UIST '21 (full paper) 🏆 nominated for best paper award Roadkill is a software tool that converts 3D models to 2D cutting plans for laser cutting—such that the resulting layouts allow for fast assembly. Roadkill achieves this by putting all relevant information into the cutting plan: (1) Thumbnails indicate which area of the model a set of parts belongs to. (2) Parts with exposed finger joints are easy to access, thereby suggesting to start assembly here. (3) Openings in the sheet act as jigs, affording assembly within the sheet. (4) Users continue assembly by inserting what has already been assembled into parts that are immediately adjacent or are pointed to by arrows. Roadkill maximizes the number of joints rendered in immediate adjacency by breaking down models into “subassemblies.” Within a subassembly, Roadkill holds the parts together using break-away tabs. (5) Users complete subassemblies according to their labels 1, 2, 3…, following 1 > 1 links to insert subassemblies into other subassemblies, until all parts come together. In our user study, Roadkill allowed participants to assemble layouts 2.4 times faster than layouts generated by a traditional pair-wise labeling of plates. |

|

[3] Fastforce: Real-Time Reinforcement of Laser-Cut Structures

Muhammad Abdullah, Martin Taraz, Yannis Kommana, Shohei Katakura, Robert Kovacs, Jotaro Shigeyama, Thijs Roumen, and Patrick Baudisch In Proceedings of CHI '21 (full paper) FastForce is a software tool that detects structural flaws in laser cut 3D models and fixes them by introducing additional plates into the model, thereby making models up to 52x stronger. By focusing on a specific type of structural issue, i.e., poorly connected sub-structures in closed box structures, fastForce achieves real-time performance. This allows fastForce to fix structural issues continuously in the background, while users stay focused on editing their models and without ever becoming aware of any structural issues. |

|

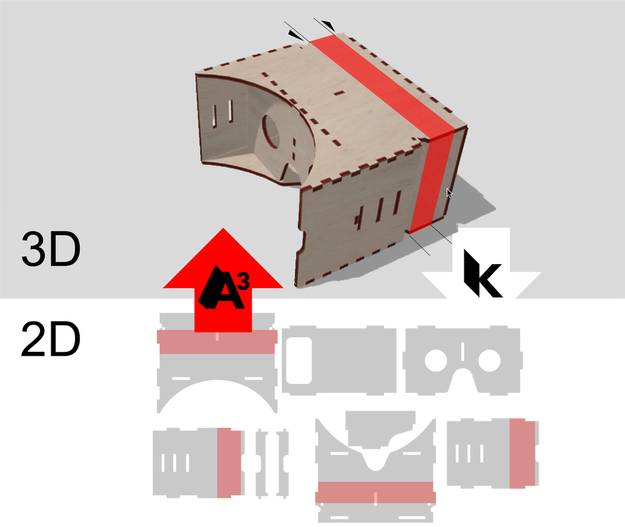

[2] Assembler3: 3D Reconstruction of Laser-Cut Models

Thijs Roumen, Yannis Kommana, Ingo Apel, Conrad Lempert, Markus Brand, Erik Brendel, Laurenz Seidel, Lukas Rambold, Carl Goedecken, Pascal Crenzin, Ben Hurdelhey, Muhammad Abdullah, and Patrick Baudisch In Proceedings of CHI '21 (full paper) Assembler3 is a software tool that allows users to perform 3D parametric manipulations on 2D laser cutting plans. Assembler3 achieves this by semi-automatically converting 2D laser cutting plans to 3D, where users modify their models using available 3D tools (kyub), before converting them back to 2D. This workflow is 10x faster than using the traditional approach of editing 2D cutting plans directly. Assembler3 converts models to 3D using a 5-step algoritm. Once reconstructed, we expect users to store and share their models in 3D, which can simplify collaboration and thereby empower the laser cutting community to create models of higher complexity. |

|

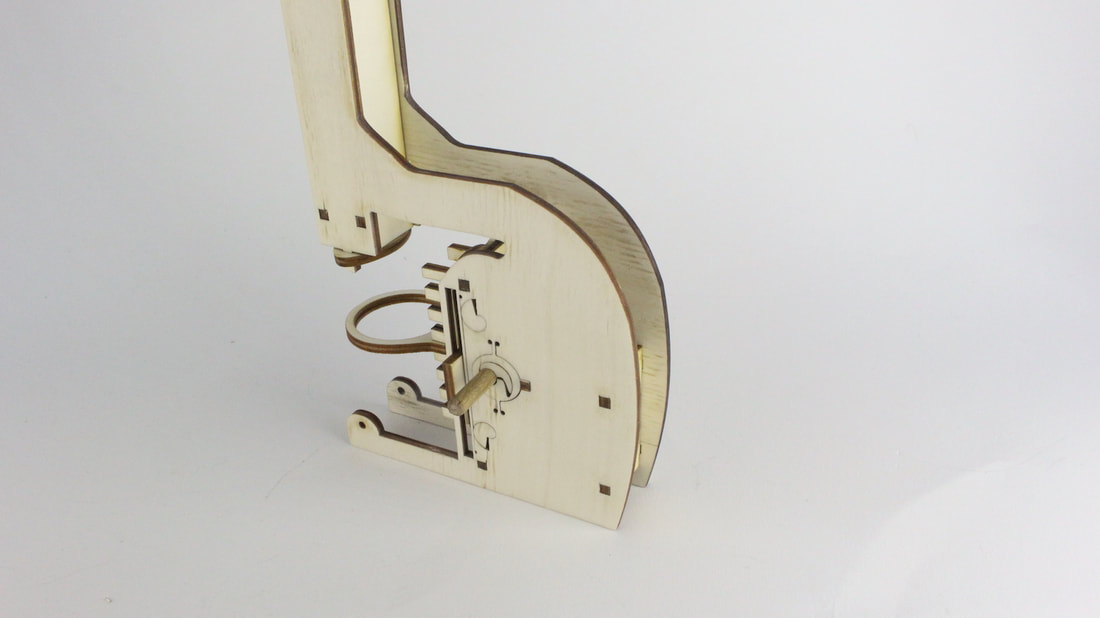

[1] Kerf-Canceling Mechanisms: Making Laser-Cut Mechanisms Operate Across Different Laser Cutters

Thijs Roumen, Ingo Apel, Jotaro Shigeyama, Abdullah Muhammad, and Patrick Baudisch In Proceedings of UIST '20 (full paper) Getting laser-cut mechanisms, such as those in microscopes,robots, vehicles, etc., to work, requires all their components to be dimensioned precisely. This precision, however, tends to be lost when fabricating on a different laser cutter, as it is likely to remove more or less material (aka kerf). We address this with what we call kerf-canceling mechanisms. Kerf-canceling mechanisms replace laser-cut bearings, sliders, gear pairs, etc. Unlike their traditional counterparts, however, they keep working when manufactured on a different laser cutter and/or with different kerf. Kerf-canceling mechanisms achieve this by adding an additional wedge element per mechanism. We have created a software tool Kerf-Canceler that locates traditional mechanisms in cutting plans and replaces them with their kerf-canceling counterparts. |

Other Publications

|

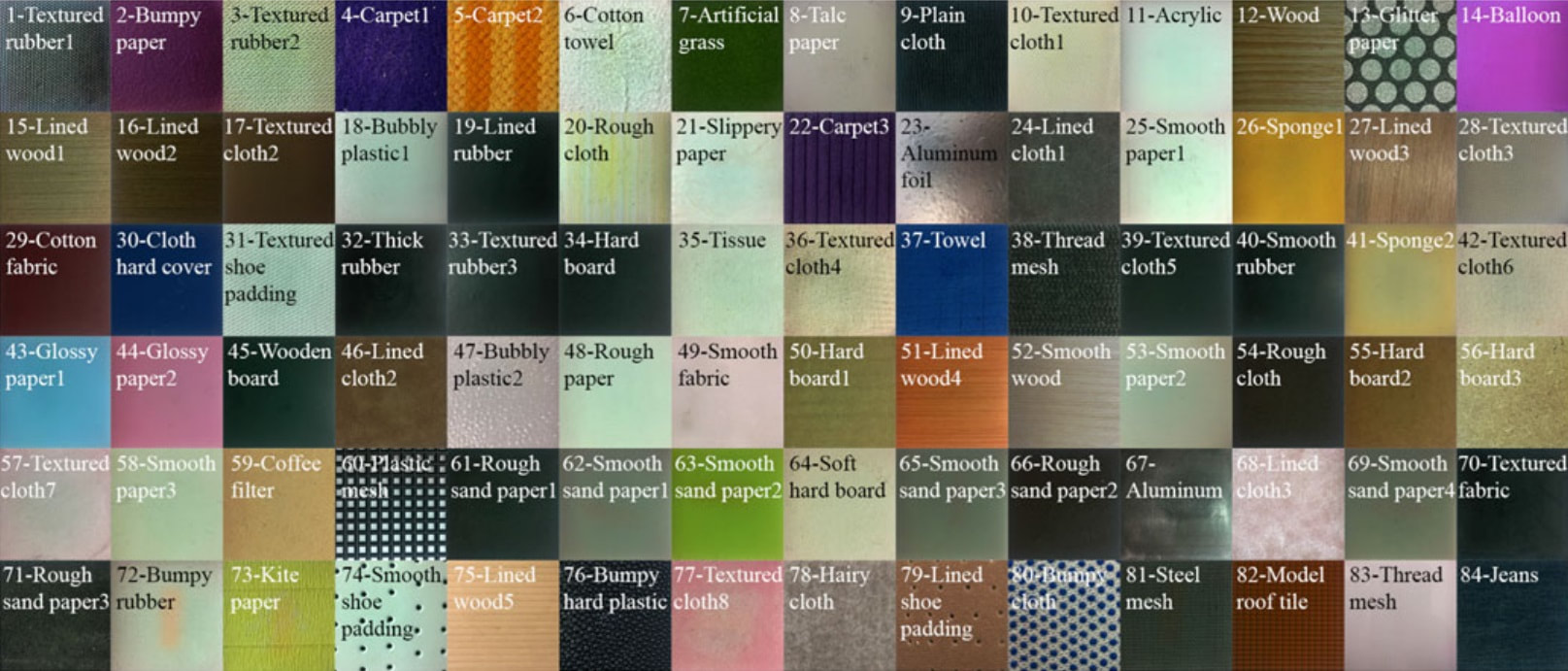

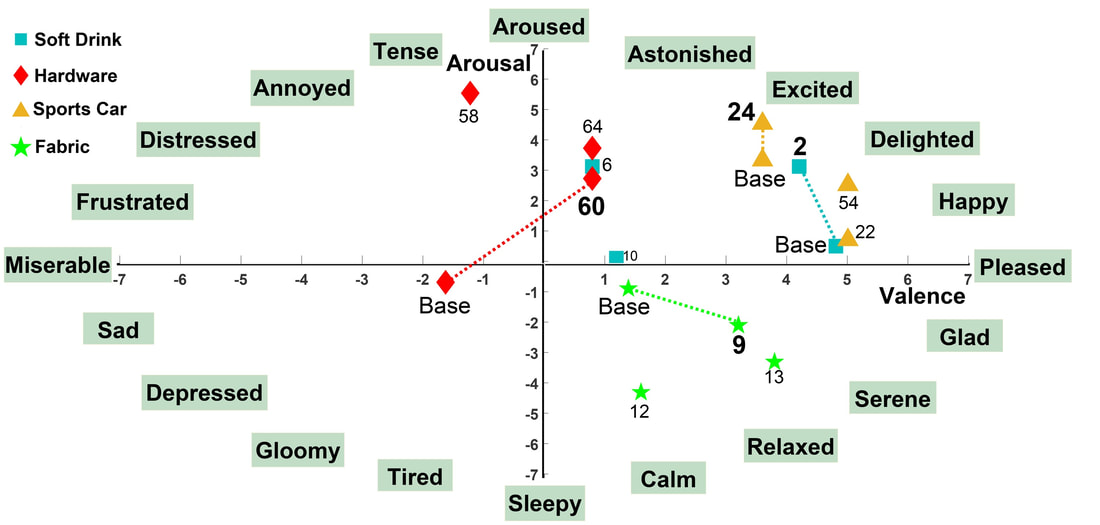

[5] Towards Universal Haptic Library: Library-Based Haptic Texture Assignment Using Image Texture and Perceptual Space

Waseem Hassan, Arsen Abdulali, Muhammad Abdullah, Sang Chul Ahn, and Seokhee Jeon IEEE Transaction on Haptics '17 In this paper, we focused on building a universal haptic texture models library and automatic assignment of haptic texture models to any given surface from the library based on image features. An image feature space and a perceptual haptic texture space are defined, and the correlation between the two spaces is found. A haptic texture library was built, using 84 real life textured surfaces, by training a multi-class support vector machine with radial basis function kernel. The system was evaluated using 21 new real life texture surfaces and an accuracy of 71.4 percent was achieved in assigning haptic models to these surfaces. |

|

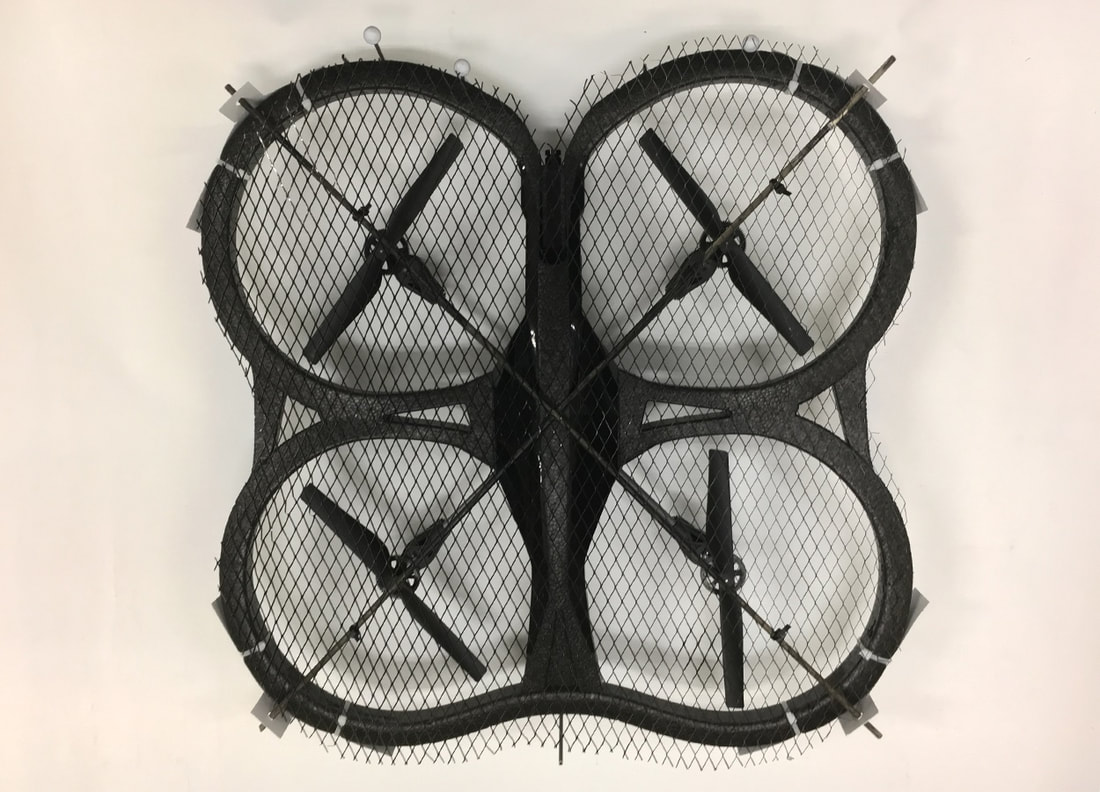

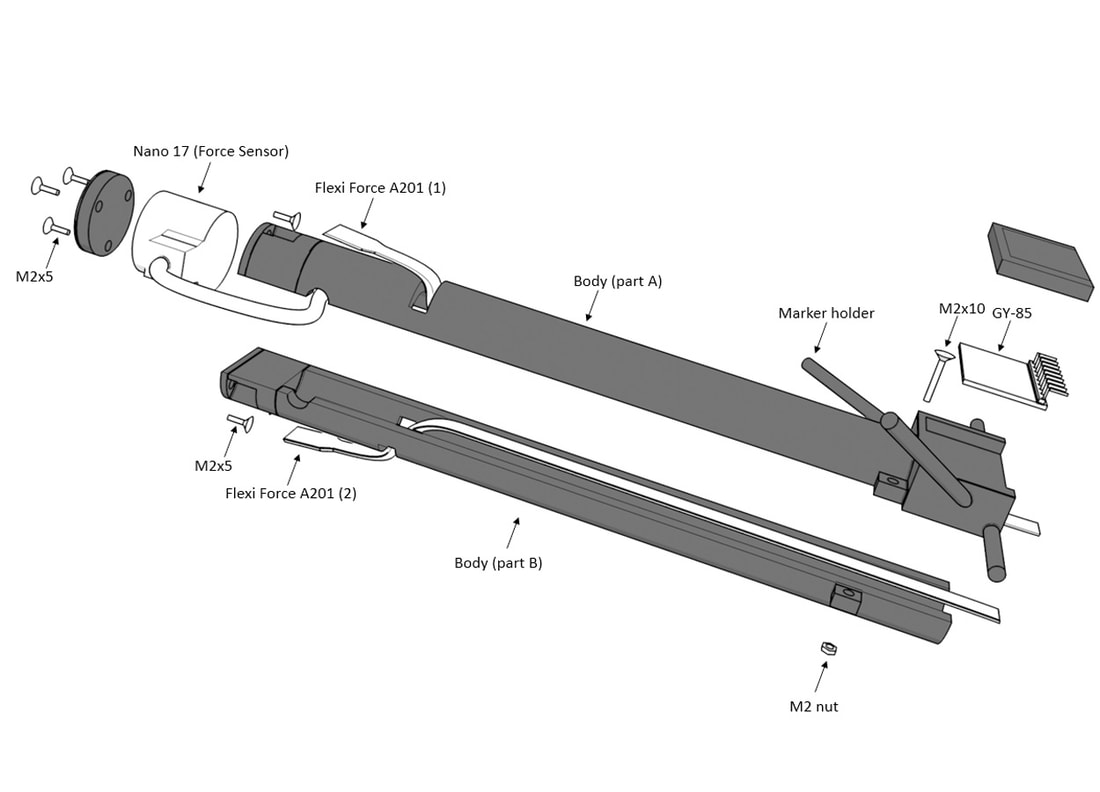

[4] HapticDrone: An Encountered-Type Kinesthetic Haptic Interface with Controllable Force Feedback

Muhammad Abdullah, Minji Kim, Waseem Hassan, Yoshihiro Kuroda, and Seokhee Jeon In Proceedings of Haptics Symposium'18 (full paper) HapticDrone is our new approach to transform a drone into a force-reflecting haptic interface. Force control is combined with tracking of drone and hand, turning the HapticDrone into an ideal end-effector for encountered-type haptics and making the system ready for more sophisticated physics simulation. Conventional stiffness and gravity simulation is merged into the encountered-type position control scheme, allowing a user to feel the softness and weight of an object. We confirm the feasibility by proving that the system fulfills the physical performance requirements commonly needed for an encountered-type haptic interface, i.e., force rendering bandwidth, accuracy, and tracking performance. |

|

[3] Haptic Logos: Insight into the Feasibility of Digital Haptic Branding

Muhammad Abdullah, Waseem Hassan, Ahsan Raza, and Seokhee Jeon In Proceedings of EuroHaptics'18 (full paper) 🏆 nominated for best paper award Companies design brands to invoke distinct perceptions in customers about their products. Currently digital consumers experience the identity of a brand subconsciously through only visual and aural logos. Although haptic properties (e.g. engrossing textures) are part of a brand’s identity in the physical world, the digital world lacks this presence. In this paper we present the concept of creating haptic logos for brands that can be digitally distributed to consumers. Haptic logos for brands were created by varying frequency, waveform and temporal properties resulting in distinct vibration patterns. We conducted two user studies: (1) assignment of appropriate haptic logos to brands by participants, and (2) judgment of the logos based on user experience and emotional response. Based on these studies, the applicability of haptic logos is discussed. |

|

[2] Tracking of Flexible Brush Tip on Real Canvas: Silhouette-Based and Deep Ensemble Network-Based Approaches

Joolekha Bibi Joolee, Ahsan Raza, Muhammad Abdullah, and Seokhee Jeon IEEE Access'20 The aim of this work is to present an alternative solution where the user's strokes can be tracked when an actual brush and canvas are used. We propose two approaches for digitally tracking the tip of flexible bristles of a soft brush. The first approach captures the silhouette of deforming bristles using a pair of well-aligned infra-red (IR) cameras, which extracts the tip from the silhouette, and reconstructs the 2D position of the tip. The second approach predicts the brush tip position through a deep ensemble network-based approach where the relationship between the brush tip position and brush handle pose are trained with our novel model comprising of Long-Short Term Memory Autoencoder and 1-D Convolutional Neural Network. The trained model is used to predict the brush tip position in realtime. Both approaches extensively evaluated through multiple tests. Furthermore, our model outperforms the state-of-the-art models. |

|

[1] HapWheel: Bringing In-Car Controls to Driver's Fingertips by Embedding Ubiquitous Haptic Displays into a Steering Wheel

Waseem Hassan, Ahsan Raza, Muhammad Abdullah, Mohammad Shadman Hashem, and Seokhee Jeon IEEE Transaction on Intelligent Transportation Systems'22 A novel steering wheel design for in-car controls is presented in this paper. The new design introduces dual ubiquitous touch panels embedded in the steering wheel for interaction with in-car controls and haptic feedback as positive reinforcement upon successful execution of an in-car control. There are eight different functionalities that can be controlled using the embedded touch panels. The proposed system is compared with a standard car regarding its efficacy using the NASA task load index (NASA-TLX) evaluation technique. The results showed that the proposed system significantly reduced the drivers’ visual, cognitive, and manual workload. |

2024 Muhammad Abdullah